Samples of Prior Work

Here, on a single page, are pictures and summaries of several projects that demonstrate my electrical, mechanical, and rapid prototyping skills.

Current employment:

Associate Program and Product Developer

Robot Sapience Ltd., Hong Kong

Here in Hong Kong, I build robots, teach children (and other teachers), and influence education policy. I'm an associate with Robot Sapience, Ltd., a small but dedicated group of teachers who travel from school to school to provide hands-on learning opportunities that students otherwise wouldn't have. One of the company's priorities is to study educational policy and the impact it has on students: their happiness, their culture, their opportunities. For my part, I teach mechanics, analog electronics, and digital electronics to students aged 12–14 for international robotics competitions: robot soccer, relay racing, autonomous navigation, and group choreography. In addition, one of my roles is to teach the other teachers about Arduino and open-source electronics, while the company tries to shift away from expensive commercial offerings.

As much as I enjoy my work at Robot Sapience, I plan to move on to another venture when my current contract runs out.

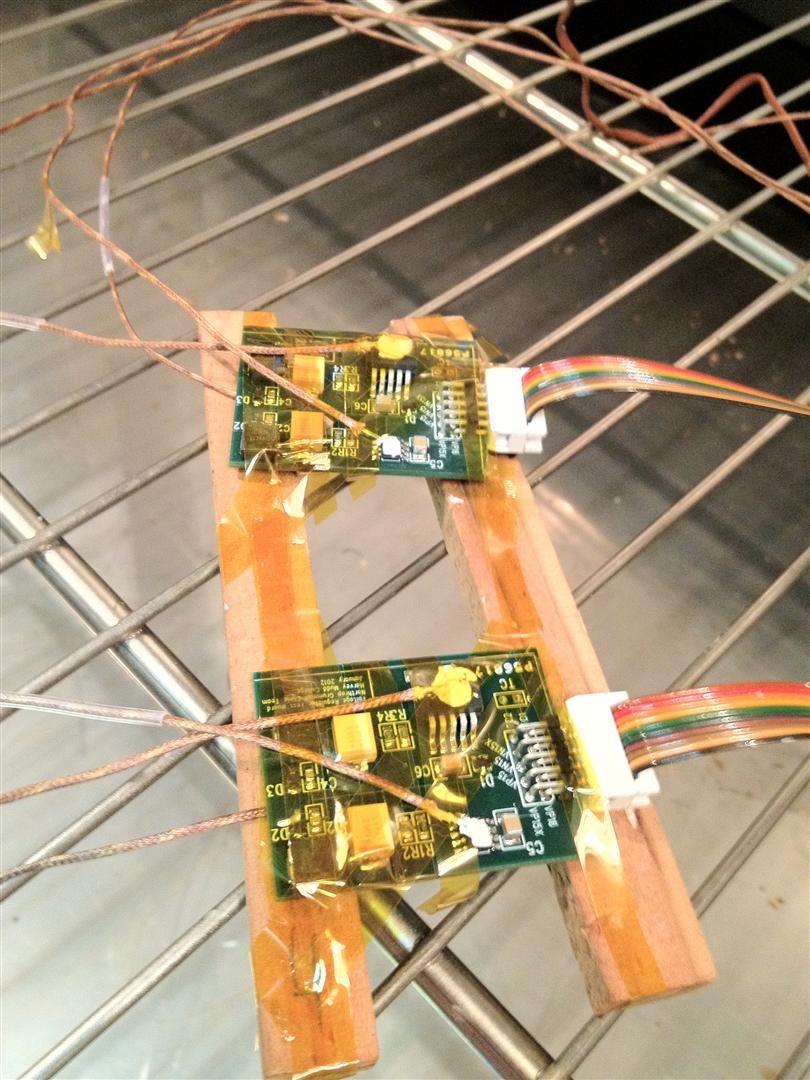

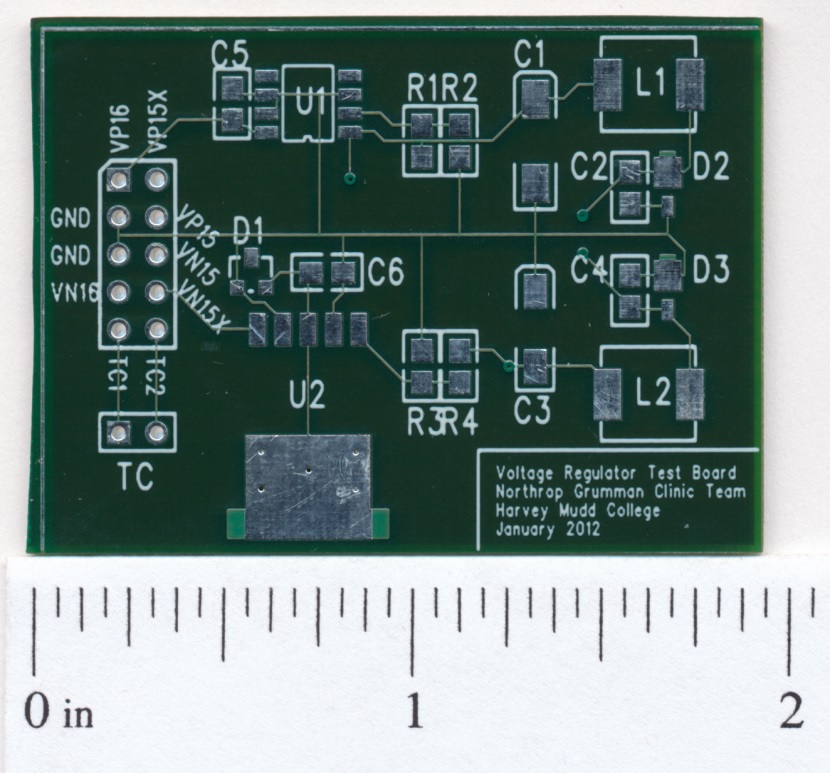

Student project for Northrop Grumman

Harvey Mudd College, Claremont, California

I designed, assembled and tested power supply circuits for a 2-Amp all-weather power supply. The intended application required very little ripple between -20°C and +50°C, even during rapid temperature changes. Not shown are the signal conditioners (simply a buffer op-amp and voltage divider) to allow my PCBs to be tested with an existing DAQ and LabView apparatus. I produced and tested several iterations to optimize.

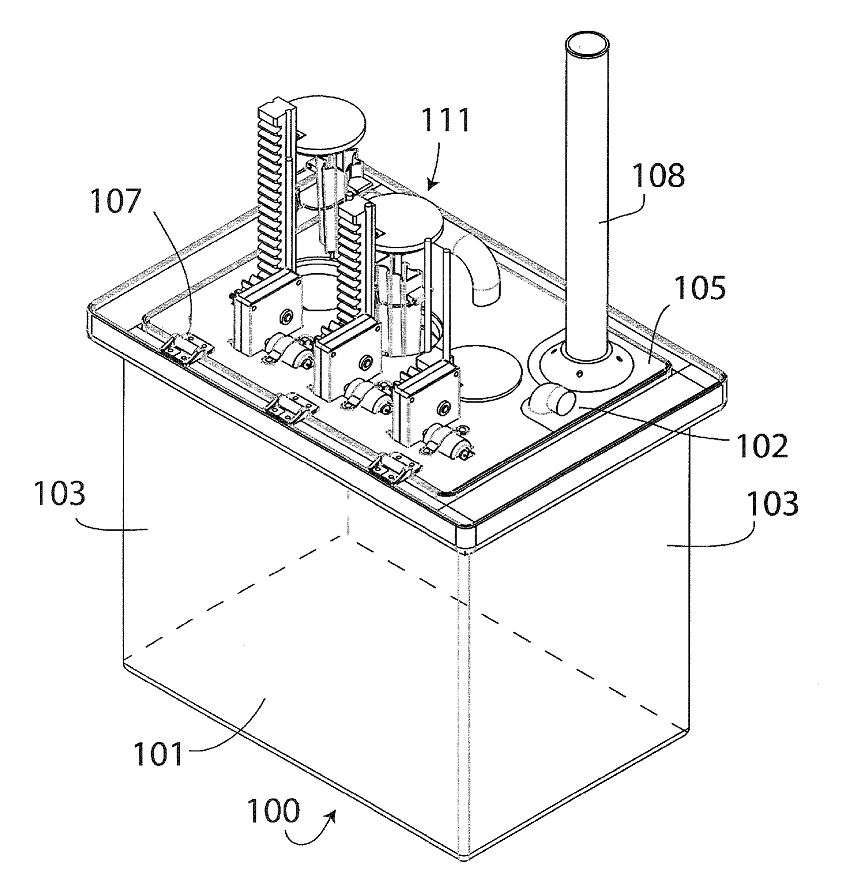

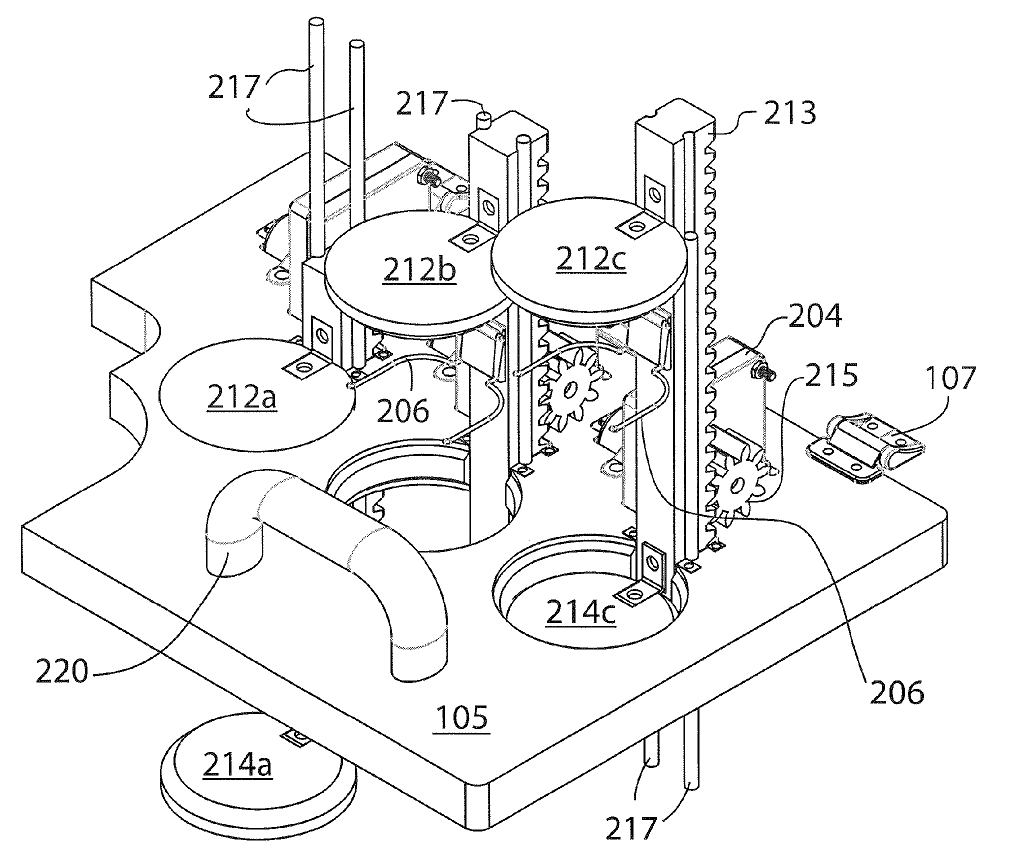

Student project for N2Pops

Harvey Mudd College, Claremont, California

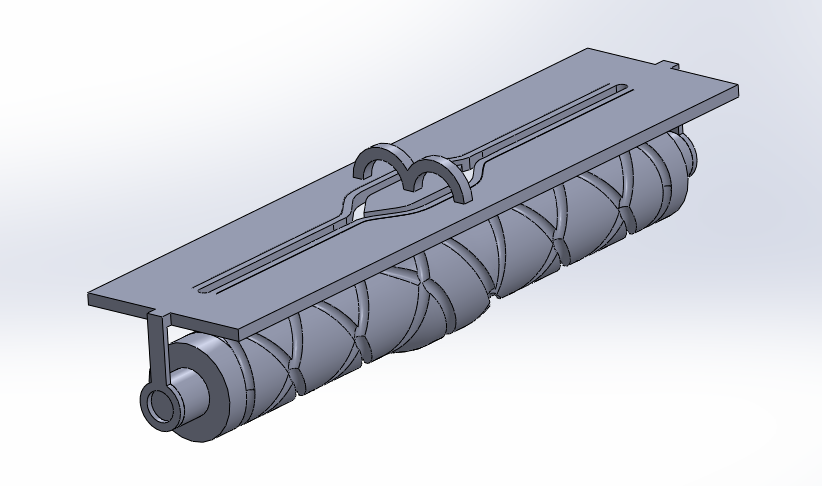

As part of a seven-person design team, I developed a product from concept to production in one academic year. The design features various electromechanical elements, working together to safely and rapidly freeze ice pops. An ARM microprocessor controls user interaction and coordinates motor activity. The design performs well, and received a U.S. patent in December 2013 (#20130333404, “Safe and compact machine for rapidly producing frozen confections”). Figures are taken from the patent document, on which I am listed as co-inventor and assignee.

Mechanical toys (personal endeavor)

I love to make things that move. I recently finished and released a small program that creates irregularly-shaped gears to produce unexpected, delightful movements. In addition, I am currently prototyping and refining two mechanical toys for my personal use. One is a 1:12 scale model of a German Baumkuchen oven, and the other is a model funicular with realistic motion. The design process has been very rewarding. I designed the belt-driven oven as a proof-of-concept for a full-size oven, complete with oven doors that open and close automatically. In addition, I wrote my own STL manipulation programs to make a barrel cam that can replicate the complex motion of a real-life funicular.

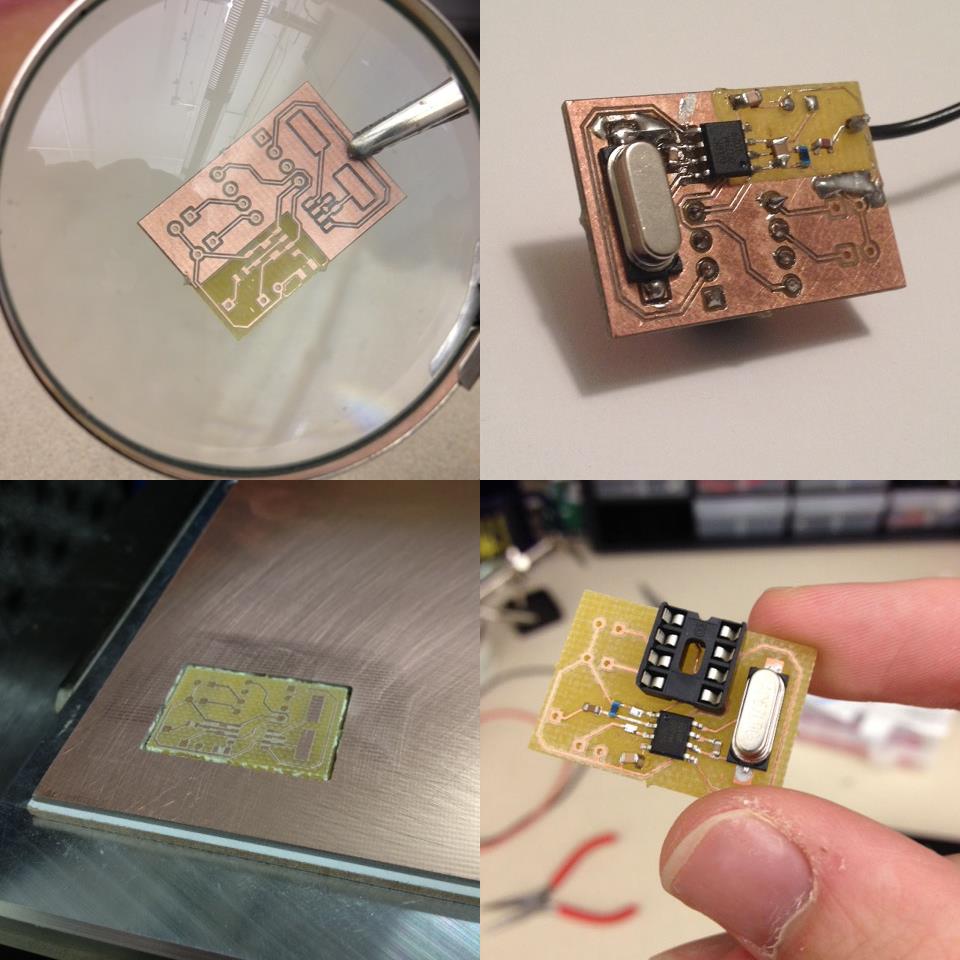

Basic Lighter-than-Air Mobile Platform (BLAMP)

Georgia Institute of Technology, Atlanta, Georgia

My professor, Dr. Magnus Egerstedt, and I collaborated on the development of a lightweight, inexpensive aerial robot to promote research in multi-agent coordination. I determined that the optimal solution was a small programmable module that could be attached to a helium balloon, making an inexpensive, easily monitored indoor airship. Shown above are renderings and schematics of the test apparatus, for checking test signals and rapidly reprogramming the system as necessary. I have uploaded a video showing successful wireless communication.

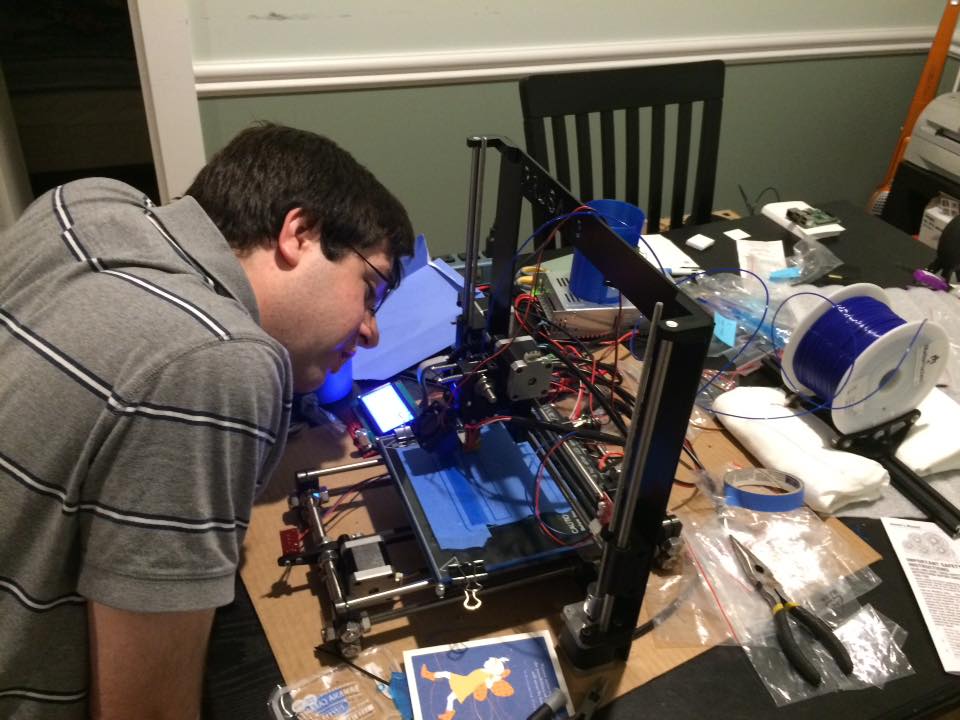

3D Printing

Everywhere I go since 2006

I spend most of my free time designing 3D models or working on my 3D printers. I currently have a Prusa i3 and a Kossel Mini delta printer in operation. Maintaining them reliably has taught me invaluable lessons on robotics (not to mention patience). Shown above are a topographical model coded and textured by me; a Lorenz attractor coded by me (for sale on Shapeways!); and my first and second home 3D printers.

Clinic Software Tutorial Writing

Harvey Mudd College, Claremont, California

At Harvey Mudd College, “Clinic” is a year-long student job for a client company. After the Clinic Director realized that many students each year were independently teaching themselves to use specific software, the Clinic Director hired me to write tutorials and save the Clinic Students lots of time. As part of the contract, I became proficient in Cadence Allegro for PCB design, SolidWorks Simulation and COMSOL for FEM/FEA analysis, and LabVIEW for automation and data acquisition. The tutorials that I wrote are still being used and provide a great service to future students.

Electrical Engineering Summer Class

Johns Hopkins Center For Talented Youth (CTY), Carlisle, Pennsylvania

CTY is a summer camp for kids, ages 12-16, who want to play and learn advanced material in a nurturing environment. Each course lasts three weeks and has two teachers for 10-16 students. As one of the Electrical Engineering teachers, I instructed students, aged 14-16, on practical and theoretical applications of electronics, starting with Ohm’s law and breadboards, and eventually building integrators and comparators for signal analysis. For a handful of more advanced students, I presented additional lessons on signal processing, frequency domain analysis, and amplitude/frequency modulation. I taught several sessions at CTY; I found it immensely rewarding to foster kids’ education and I hope to return at some future time.